Laser Welding E-Mobilitiy

The production of electric motors, power electronics and batteries places the highest demands on laser-based production tools.

Laser beam welding is an excellent choice even for small components and assemblies. Examples can be found in precision engineering or electrical contacting, such as hairpins for e-mobility. This requires generally very precise and automated recognition of the welding position as well as laser beam welding with beam oscillation.

The laser welding optics from Scansonic assume these demanding operations. The energy input through the laser is scalable both locally and temporally and is therefore exactly adaptable to the joining process.

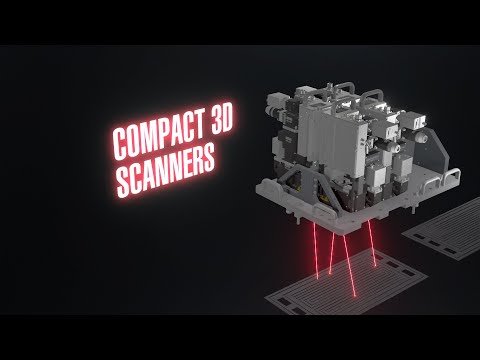

The product portfolio ranges from simple processing optics for deep or thermal conduction welding to complex systems with automatic welding position detection, fast beam oscillation and process monitoring.